1. Handan Xinniu Agricultural Technology Co., Ltd. was completed the industrial and commercial registration on March 2, 2021;

2. Handan Xinniu Agricultural Technology Co., Ltd. was completed the recruitment of technical, sales and production personnel on March 10, 2021. The employed personnel are all the technical experts, technical backbones, sales managers, management elites and production backbones of the original Handan Golden Lion Cotton Machine Co., Ltd. to ensure the technical inheritance and continuous improvement, stabilize the market sales channels and manufacture high-quality products.

3. On May 26, 2021, Handan Xinniu Agricultural Technology Co., Ltd. invested in Xinjiang Xinniu Hengxin Trade Co., Ltd., accounting for 42% of the shares; Mainly engaged in cotton machinery accessories, agricultural machinery accessories and other products.

4. On June 8, 2021, Handan Xinniu Agricultural Technology Co., Ltd. applied for and obtained the certificate of foreign trade operator.

5. On June 25, 2021, the company held a technical seminar to discuss the structural upgrading of production equipment this year, so as to ensure better equipment production indicators and cotton processing indicators. The participants are the company's design engineers, technical service backbones and specially invited industry technical experts.

6. On September 10, 2021, the company successfully completed the supply of this year's order, held a production summary meeting, and summarized the improvement, problems and improvement measures of the new process in this year's equipment production process. At the same time, arrange and deploy after-sales service plan, and implement after-sales technical service personnel and technical training.

7. Through market analysis, combined with its own core technology, on October 15, 2021, through technical demonstration, it was determined to develop a 152 saws, 19.4mm large gin with a single desktop output of 1500kg to 1800kg; The research and development of this product will improve the output on the basis of maintaining the quality and length of raw cotton. The five 152 gin production lines can meet the full load operation of 400B2 baling machine, improve the overall production efficiency and reduce the processing cost.

8. On October 20, 2021, the double boll clearing process and equipment provided by Handan Xinniu Agricultural Science and Technology Co., Ltd. to Awati Xinya Cotton Industry Co., Ltd. were successfully tested. The implementation of this project has realized that a production line can process both fine cotton and long cotton, which will reduce the repeated investment of users.

9. In November 2021, through the efforts of the technical team, the development of an efficient cleaning system for sterile seed cotton was completed, and the trial production was completed and shipped to Xinjiang.

10. In order to expand the production scale, the overall relocation of the plant will begin on January 5, 2022, from Yongnian District, Handan City to Shenglong Equipment Industrial Park, Fuxing District, Handan City. The relocation was completed on January 11, which improved the working environment and equipment processing capacity.

11. On May 17, 2022, "a sterile seed cotton processing production line, patent number: ZL 2021.2.3327626.8" applied by Handan Xinniu Agricultural Technology Co., Ltd. was authorized as a utility model patent by the State Intellectual Property Office.

12. On May 28, 2022, Handan Xinniu Agricultural Science and Technology Co., Ltd. and Kuitun Taixin Cotton Industry Co., Ltd. signed a turnkey project cooperation project for six 152 gin production lines, marking that the large-scale 152 gin has officially entered the cotton processing market.

13. On June 20, 2022, Handan Xinniu Agricultural Science and Technology Co., Ltd. and Fengyuan Science and Technology Co., Ltd. of Awati County Academy of Agricultural Sciences reached a cooperation agreement on the experimental research of the machine picked long staple cotton three thread free processing production line. It is proposed to research and develop an intelligent sorting and multi-level impurity removal processing method to achieve the intensive, efficient and standardized production of machine picked long staple cotton in Xinjiang through the joint research of "interdisciplinary and multi professional".

14. On August 2, 2022, "a production line capable of processing machine picked long staple cotton and machine picked fine staple cotton, patent number: ZL 2021.2.3217027.0" applied by Handan Xinniu Agricultural Technology Co., Ltd. was authorized as a utility model patent by the State Intellectual Property Office.

15. On September 20, 2022, the overall installation and commissioning of the 6 sets of 152 type cotton picking and ginning complete production line project of Kuitun Taixin Cotton Industry Co., Ltd. will be completed on schedule.

16. September 21, 2022, Handan Xinniu Agricultural Technology Co., Ltd. Achieved "A ginning machine with an adjustment device in the upper miscellaneous area"Patent, patent number: 2022225016761, improve the control ability of the ginning machine on mote containing white cotton.

17. December 19, 2022, Handan Xinniu Agricultural Technology Co., Ltd. achieved "A kind of long-staple seedcotton bell clearing machine"Patent, patent number: 2022233915181; the application of this patent will change and improve the cleaning effect of machined-picked long-staple cotton.

18. On January 5, 2023, the company organized technical, sales and service personnel to hold an after-sales service summary meeting, found problems or potential problems in the use of equipment, and determined improvement plans to help improve product performance and create greater value for users.

19. March 6, 2023, Handan Xinniu Agricultural Technology Co., Ltd. achieved"A serrated lint cleaning machine"Patent, patent number: 2023203886540; innovation breaks through the existing technical level in China and reduces the damage to the fiber length.

20. March 10, 2023, Handan Xinniu Agricultural Technology Co., Ltd. Achieved "A V-shaped miscellaneous knife for rack and roller row of cleaning machine"Patent, patent number: 2023204412787; the application of this patent strengthens the machine-picked cleaning efforts of bell shells and cotton stalks improve the quality index of machine-picked cotton processing.

21. On April 13, 2023, Handan Xinniu Agricultural Technology Co., Ltd. signed a foreign ginning and delinting production line in Tajikistan, contributing to the country's foreign exchange creation.

22. May 12, 2023, Handan Xinniu Agricultural Technology Co., Ltd. achieved"A recycled seed cotton cleaning machine"Patent, Patent No.: 2023211449358; The beneficial effect of the utility model is that by promoting the movement of the platform, the impurities at the lower end of the cleaning box can be pushed into the recycling box, which can facilitate the collection of impurities.,Preventing the collected impurities from returning to the cleaning box can improve work efficiency.

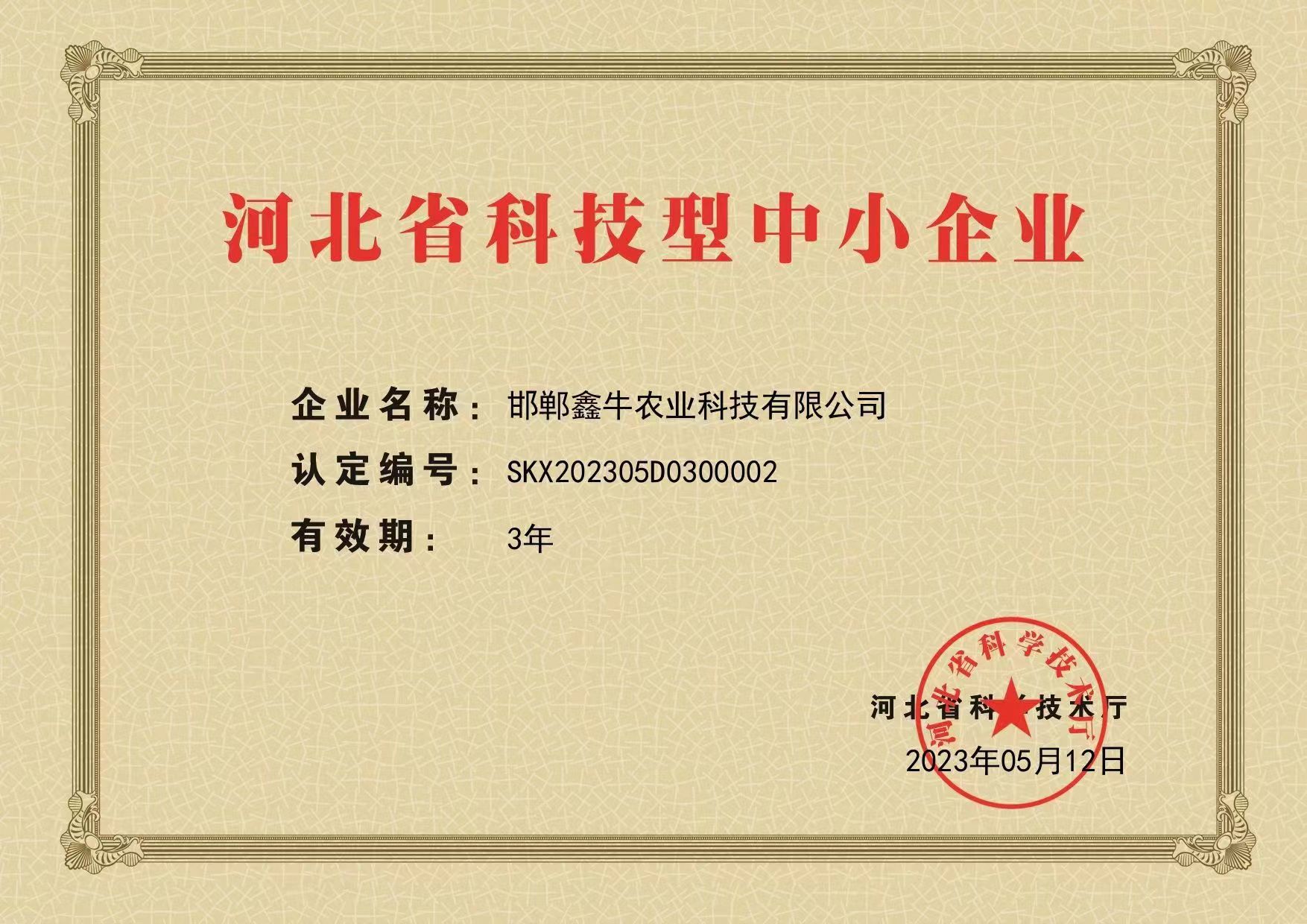

23.May 12, 2023, Handan Xinniu Agricultural Technology Co., Ltd. It is recognized as a science and technology-based small and medium-sized enterprise in Hebei Province by the Department of Science and Technology of Hebei Province, with identification number: SKX202305D0300002.Science and technology-based small and medium-sized enterprises are awarded by the Ministry of Science and Technology Honour. It is the "certification" of enterprise innovation ability, and it is the sign of increasing brand influence and intangible assets of enterprises

24.On May 20, 2023, Handan Xinniu Agricultural Technology Co., Ltd. and Wusu Guertu Agricultural and Animal Husbandry Development Co., Ltd. signed a turnkey project for the machine-picked production line of 6 units of 152 gin.

25.May 27, 2023, Handan Xinniu Agricultural Technology Co., Ltd. achieved"An automatic seed cotton feeder with cleaning function"Patent, Patent No.: 2023213105877; the utility model Patent The suction tube is moved by the swing frame, which can increase the suction range of the suction tube, and then it is easy to absorb the seed cotton into the feeding box. The impurities on the seed cotton can be cleaned up through the nail roller group, which reduces the labor intensity of the staff and improves the work efficiency.

26.On June 23, 2023, the Institute of Economic Crops of Xinjiang Academy of Agricultural Sciences and Handan Xinniu Agricultural Technology Co., Ltd. Joint application and obtain"A high-efficiency seed cotton bell machine for harvesting long-staple cotton"Patent, patent number: 2023216002302; the processing machine adopts a high-efficiency seed cotton bell machine for long-stapleseed cotton, which can make seed cotton more loose, clean up impurities, and improve the cleaning effect.

27.On July 15, 2023, the ginning and delinting production line in Tajikistan has been completed and shipped.

28.On August 21, 2023, Director Ruan Xuliang of Zhengzhou Cotton&Jute Engineering Technology and Design Institute of China Supply and Marketing Cooperative Association led four relevant technicians.ArriveOur company carried out research and carefully investigated the seed cotton impurity cleaning machine.TaxiProduction and technological innovation of new ginning machines, and carry out in-depth exchanges on the collaborative transformation of scientific research achievements, jointly accelerate the transformation and market promotion of technical achievements, promote the technological progress of cotton processing intelligent testing equipment, and serve the high-quality development of the cotton industry.

29.On November 16, 2023, Handan Xinniu Agricultural Technology Co., Ltd. passed the GB/T 19001-2016/ISO 9001:2015 quality management system certification. It shows the company's quality management level of integrity, scientific, normative, and laid a solid foundation to meet the needs of customers.

30.On December 2, 2023, Handan Xinniu Agricultural Technology Co., Ltd. was absorbed by the China Cotton Association as a member unit, and the membership of the member will have a certain influence on the enterprise in its business field.

31.On April 2, 2024, Gao Yunlong, director of Zhengzhou Cotton and Linen Engineering Technology Design Institute of the All-China Supply and Marketing Cooperative General Association, and 4 related technical personnel visited our company for investigation.